TIPS AND FREQUENTLY

ASKED QUESTIONS

|

|

Understanding Shell

|

| Oanh - She and her husband manage our shop in Viet Nam. |

|

Engraved Mother Of Pearl Shell

This engraving of Ho Chi Minh was done by |

|

Details were from this 100,000 Dong note. |

|

The artist signing his work. |

|

Another view of Ho by the same artist. |

|

There are aspects of the art of inlay and the understanding of shell that are not obvious that you should know. I will try to explain some of these here. What is shell and how does it come to be. Shells are made up of calcium carbonate. All shells, whether they are from an oyster, clam or snail are built up in layers as the animal grows. |

|

|

|

Red Abalone Shell Cut Open.

Red Abalone is Unavailable |

|

|

After a blank is ground out of a shell it will have one side that is better looking than the other. The reason for this is because you are looking at light reflected off the surface of the shell blank. The side of the blank that was the outside of the shell will scatter the reflected light and seem to be brighter. The other side of the blank will gather the light and consolidate it making it appear darker and less reflective. Wherever possible you will want to use the outer side of the shell blank to show of the color best. |

|

Shell processing done as shown in these pictures with the machines shown below. All the machines are made special for us. After the first hand grinding on a wet stone wheel of the blanks to about 2mm thick, then blanks are fed through the grinder several times until the desired thickness is achieved. We then have the shell blanks that we sell and use for all the inlays we make. We control the process from raw shell to cut inlays to control quality. |

|

|

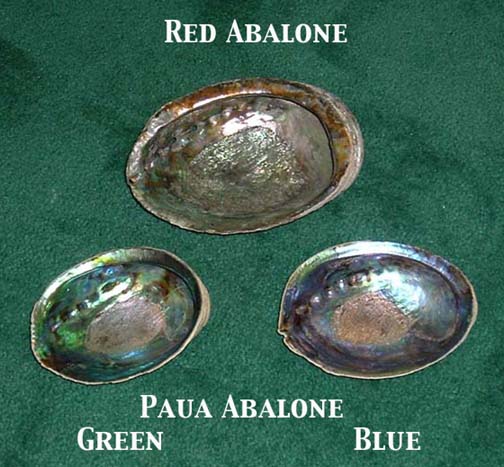

It's come to my attention that several dealers out there are selling Paua and other shell products that are not real solid shell blanks or good quality shell blanks.They are using deception to make the buyer think they are going to get the best quality shell blanks. First let me explain a little about Paua Abalone so you will be able to follow what I am telling you. Paua is the most beautiful abalone shell there is. It has the strongest color of any shell anywhere. That's the good news. Bad news is that most of the shells are small and thin with a lot of worm damage. Of all the shell's harvested, only about 5% of the shells that are thick enough to give nacre that is acceptable for making solid blanks. These are the older abalones that have been missed during earlier fishing. Just like people, Abalone grow fast and slim until they are adult size... Then just like us, they start getting thicker. As an example, we bought a container load (8.5 metric tons) of the shells from New Zealand. Out of all this only 400 kilos were "J" grade ("J" is for Jewelry), thick shells. |

|

|

White MOP Shells.

|

|

The rest had to be sold in Asia where they use much thinner blanks than we do in the west. They also do not mind the blanks with worm holes and outer bark on the back side because they inlay flush with the surface. |

|

|

Gold Lip MOP Shells. From these we get both Gold MOP and White MOP Blanks. |

|

Because the blanks must be cut and ground from curved shells, most of the material gets ground away to produce the select quality blanks. For us the result was that only 400 kilos (880 lbs) of raw shell were "J" grade, resulting in about 30 kilos (66 lbs) of best quality shell blanks. The rest is all ground away and lost in the processing. One operator is cutting his blanks from lower grade shells and leaving a valley in the surface. He is then filling the valley with epoxy and passing that off as "an old inlay secret". All I can say about that is "BS". Epoxy will not buff out the same as shell, so the end result will be very poor no matter what you do. Simple fact is that you can not get good select grade blanks from thin shells. End of discussion. |

|

|

Abalam:Abalam is a product that was developed by Chuck Erikson (The Duke of Pearl) and his friend Larry Siffel. I have known Chuck and been a customer of his for thirty years. For ages he was the only one selling good quality shell products at great prices. I know of nobody who has ever felt that Chuck has been anything but a great fellow who is as honest as the day is long. He has been the main supply of shell products for luthiers (Directly and indirectly) for many years. Please do not think that my view of abalam has anything to do with my great respect for Chuck. |

|

|

Abalone Shells before processing.

|

|

Abalam is made from the thinner grades of shells that are of no use for shell blanks. Even these thinner shells have great color and finding a way to use these for inlay work is a great thing. Abalam has some great value for some kinds of inlay work. I find it to be wonderful for doing the purfling strips around the edge of the guitar and in the 1/16" wide rosette strips. This is because it breaks into the channel so well and looks very good when finished under lacquer. I prefer using abalam there to using solid shell strips. It is much faster, and to my eye, I find it better looking. Some luthiers do not agree on this. |

|

|

|

Abalam is made by cutting the shells up using band saws with thin diamond blades. The shells are cut along the curve of the shell so that the result is long thin Strips. Shell that is thin can be flattened a little without breaking. Those strips are then sanded to a thickness of about .010" to .015". Next they are edge glued to each other to make up sheets a little over 5.5" X9". The sheets are then sanded smooth to a thickness of about .005" to .010". Next step is to layer these with epoxy glue to the desired thickness, be it .030", .040", .050" etc. At last, the large " Blank" is trimmed to it's standard size of 5.5" X 9". Some of these are then cut up into straight strips for purfling and curved strips for rosettes. Others are sold as full size sheets for inlay artists. There is a great article in Guitar Maker #38 with much more detail on all of this. |

|

|

|

Now let me tell you what I do not like about abalam. While it is good when you need to cut an inlay that is larger than any blank, I would rather pick out matching shell blanks and joint them because that allows me to choose where the joints will be. I used abalam once in a fret board, very bad idea. After I sanded the radius into the fret board, I'd sanded down through some layers of shells that did not match well at all. The next problem was that because of the way that the abalam layers are glued up, there were pockets of solid epoxy, yuck.... This epoxy will not buff out to the same high shine that the shell will. Result was a very uneven look that was not good. I will never try this again. On that same guitar I made a 3/4" wide single piece abalam rosette. It was also not as good looking because after sanding, some of the shell layers were so thin that I could see the next layer of shell through the top layer. It just looked weird. There were also air pockets in the epoxy that needed to be filled. In the end I felt the guitar was not as good as it would have been if I'd used solid shell. In today's age of computer cutting of inlays and the pockets that they go into, abalam makes for a great product. The operator can set all his programs to cut the maximum number of inlays from a sheet of abalam. But when he tells you these are selected matching sections, well I doubt it. I have seen a site on the web where people selling abalam products are calling it solid shell. It is no more solid shell than plywood is solid wood. The old saying holds, if it seems too good to be true...... You know the rest. |

|

|

Red Sea Snail. This is a very popular shell in Asia for its wonderful peach color and strong rose pink color flash. We no longer process these because the cost has gone so high. |

Shell Blank Thickness Information:We sell our shell blanks in several thicknesses, from .020" (.5 MM) to .080" ( 2 MM).... What does this mean? We grind most of our shell blanks in our own shop. Other shell blank products are bought from other processors. The quality control is better on the ones we process. This is how we process our blanks:The shells are cut into sections with very this saw blades under water. Next they are rough ground (On a wet stone wheel) to get one surface very flat and then the other side is ground to a little thicker than the finished thickness.The last step is when we pass these blanks through a special machine that was built for us. This machine has a diamond cutting wheel. Blanks are fed into the machine on a hard rubber feed belt. Results are quite good and we are able to get the blanks very flat and close to thickness. Generally, within 0.004 inches of target. If a blank is labeled as 0.060 inches it will not be under thickness, but a may be a bit over. End result is that the blanks are quite good but not all exactly the same thickness. Softer shells, Such as abalone come out closer than mop which is harder. Because of the above, most of the blanks you buy from us will be right on or very close to the advertised thickness. |

|

| Sorting blanks for quality and size. |

|

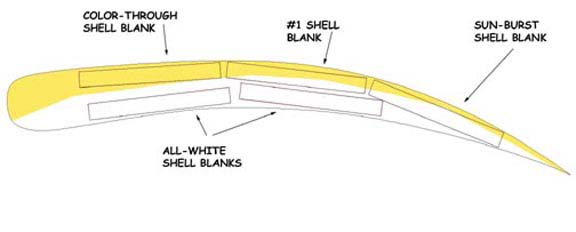

Gold lip shells are gold on the outside and white on the inside. From these we get Gold MOP, Gold Sunburst MOP and White MOP. The White MOP from this shell is a warmer white with very strong color flash. From some very large shells we are able to get guitar and mandolin nuts. White lip shells are white inside and out. The blanks from these shells are very white with less color flash. The shells are also often larger and provide the best number of blanks from each shell. From some very large shells we are able to get guitar and mandolin nuts. Black lip shells are smaller and this is where we get Black MOP, Black Sunburst MOP and White MOP. The " black" is not always black, some is brownish or grayish. Most has very nice color flash. The white blanks we get from this shell tend to be very silvery white. |

|

|

Cut away view of Gold MOP shell.

|

|

The ratio of gold or black blanks to sunburst and white blanks varies from shell to shell because the color layer (Be it Black or Gold) tends to be thin. And because of this, most black or gold blanks will have color on one side and be white or mixed on the other side. Blanks that have the black or gold color through out the thickness of the blank will be sold as “Select Blanks” at a premium price because there are far less of them. You will need to inlay the regular blanks very close to the surface to avoid sanding away the color layer. This is fine for flat inlays. For fret boards that will be radiused after the inlay is in place, you should pay a little more and get select (color-through) shell blanks. |

© Copyright 2013 LuthierSupply.com. All Rights Reserved